The rubber hose is very important for sand blasting. It can not only affect the sandblasting effect, but also ensure the safety and durability of the work. This article will introduce how to select the hose suitable for fine sand blasting, and some related precautions.

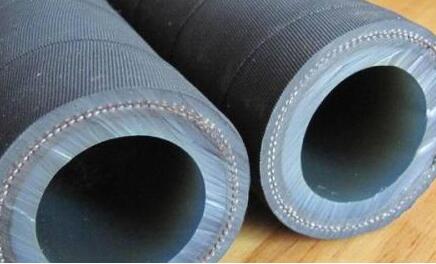

First, select Sandblasting hose The material should be considered. High quality rubber hose shall have the characteristics of wear resistance, pressure resistance and corrosion resistance, and be able to maintain stable performance in a long time of sand blasting work. Common hose materials include rubber, polyurethane and polyethylene. Each material has its own characteristics and application scenarios. Choosing proper hose material can improve sandblasting effect and prolong service life.

Secondly, the length and diameter of the hose also need to be selected according to the specific situation. Moderately long Sandblasting hose It can provide flexibility and convenience to make the work more smooth. The rubber hose with proper diameter can ensure the fluidity of sand blasting materials and avoid blocking and damage. Therefore, proper length and diameter shall be selected according to actual needs when purchasing rubber hoses.

In addition, attention should also be paid to the connection mode of the hose. Sandblasting hose The connecting pieces are under great pressure during sand blasting, and they need to be removed and installed frequently. Therefore, it is very important to select connectors with good pressure resistance and firm connection. Common connection methods include threaded connection, clamp connection and quick connector connection. Each connection method has its own application scenarios.

To sum up, select the appropriate Sandblasting hose It is the key to ensure the work effect and safety. Proper selection of hose material, length, diameter and connection mode can improve sandblasting effect, extend service life and ensure smooth operation.