Sandblasting hose Usually Abrasion resistant sand blasting hose It is a kind of material conveying pipe.

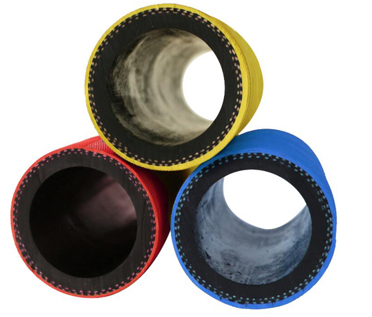

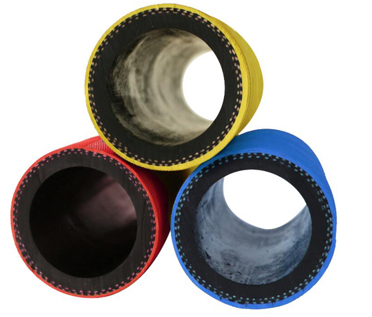

Product appearance:

Common black, yellowish or transparent; The outer rubber packing belt is mostly used for wrapping, and the steel wire is usually used between the inner and outer rubber to apply to the negative pressure working condition.

Product use:

It is mainly used for conveying solids containing particles such as particles, gravel, cement, quicksand, concrete, gypsum, etc. It is suitable for various tunnel projects, tunnels, caverns and other engineering industries.

Common materials:

The inner rubber and outer rubber of sandblasting hose are usually made of wear-resistant materials, most of which are NBR (acrylonitrile butadiene copolymer), SBR (oil extended styrene butadiene rubber), or a kind of PARA rubber (trefoil rubber) with better performance of imported hose.

Common types:

Sand blasting hose is generally classified into light type according to working conditions and the loss of material particles to the conveying medium Sandblasting pipe And heavy sandblasting pipe with spiral steel wire will make it suitable for negative pressure environment.

1. Light sandblasting pipe:

It is usually used in the use environment such as ship sand blasting and quicksand operation; The common inner rubber is made of wear-resistant NBR (natural rubber) material, and the outer rubber is wrapped with composite rubber.

2. Heavy sand blasting pipe:

It is used for equipment sandblasting sand gravel, fine pebble, mud and other use environments.

3. Sand blasting vacuum pipe:

Spiral steel wire is embedded, and the general vacuum negative pressure can reach 0.9 bar.

Common parameters:

Abrasion resistant sand blasting pipe Generally, there are the following parameters:

Pressure: Generally, the working pressure is within 12 bar, and the bursting pressure can reach 36 bar if it is high. Sometimes, vacuum negative pressure parameters such as 0.8 bar~0.9 bar are required.

Temperature: the common temperature range is - 30 ℃~+80 ℃

Wear resistance coefficient: common wear resistance coefficient is 60~75m3

Diameter and wall thickness: diameter and inner diameter of the hose. The wall thickness usually refers to the thickness of the inner rubber, and the outer diameter refers to the outer circle.