The manhole cover industry is changing, and a new material manhole cover is occupying the market

Sandblasting hose Strict requirements for processing and production: sandblasting hose is also a common type of hose for transportation. Here are the specific precautions for sandblasting hose processing and production:

1. Wear protective equipment before processing sand blasting hose, and do not work with bare arms.

2. The air receiver, pressure gauge and safety valve shall be calibrated regularly. Dust is discharged from the air tank once every two weeks, and the filter in the sand tank is checked once a month.

3. Check whether the ventilation pipe and sandblasting machine door are sealed. The ventilation and dust removal equipment must be started five minutes before work. When the ventilation and dust removal equipment fails, the sandblasting machine is forbidden to work.

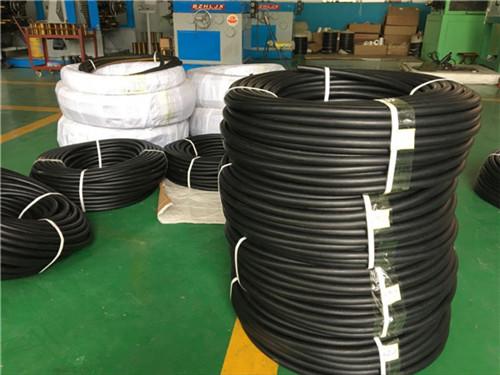

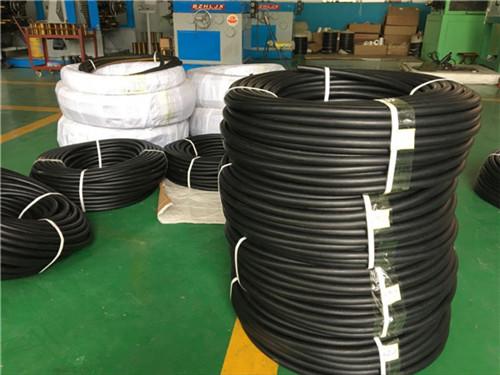

Sand blasting hose is a kind of material conveying hose, which is used to convey frosted media with large friction coefficient. This type of hose usually has ultra-high wear resistance characteristics. The rubber layer inside the hose is made of NBR wear resistant rubber, but there is no strict requirement for pressure. The pressure of 12BA is considered as high pressure;

Sandblasting hose structure

1. The outer rubber layer adopts SBR/NR mixed conductive rubber;

2. The inner rubber layer is made of NBR high wear-resistant rubber.

3. Reinforcing layer adopts high tension textile cord, commonly known as cord, so one type of sandblasting hose is cord Sandblasting pipe 。 Litong sandblasting hose adopts double-layer textile rope skeleton layer.

Sandblasting pipe Characteristic Common temperature range: - 30 ℃~+80 ℃ Common wear coefficient: 60~75 cubic mm General working pressure;