Why do metal surfaces need sand blasting? below Sandblasting hose The manufacturer's small editor will take you to understand this reason!

(1) Sand blasting before workpiece coating and workpiece bonding can remove all dirt on the surface of the workpiece, such as rust scale, and establish a very important basic schema on the surface of the workpiece (commonly called rough surface). Moreover, it can achieve different degrees of roughness by changing abrasives of different particle sizes, such as the abrasives of flying abrasive abrasives, greatly improving the workpiece and coating Binding force of plating material. Or make the bonding parts more firm and better quality.

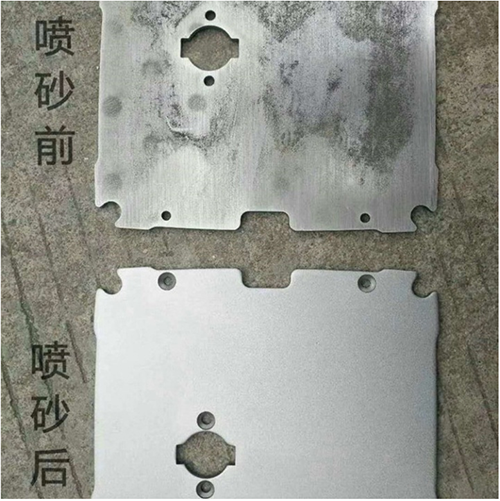

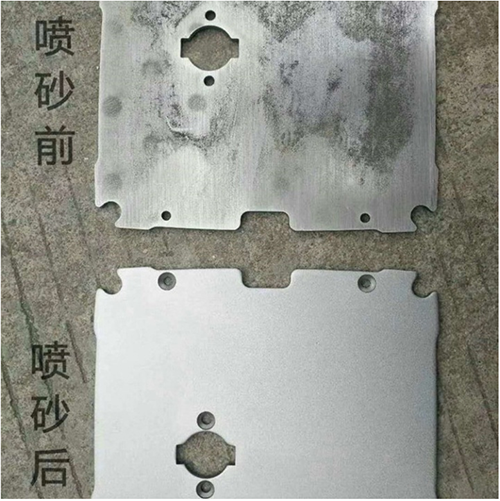

(2) The cleaning, polishing and sandblasting of the rough surface of the casting parts and the workpiece after heat treatment can clean all the dirt (such as oxide skin, oil stain and other residues) on the surface of the casting forgings and the workpiece after heat treatment, and polish the surface of the workpiece to improve the smoothness of the workpiece, so that the workpiece can expose a uniform metal color, and make the appearance of the workpiece more beautiful and good-looking.

(3) Burr cleaning and surface beautification sandblasting of machined parts can clean the tiny burrs on the surface of the workpiece, make the surface of the workpiece more flat, eliminate the harm of burrs, and improve the grade of the workpiece. In addition, sandblasting can make a small round corner at the junction of the workpiece surface, making the workpiece more beautiful and precise.

(4) Improve the mechanical properties of parts After sandblasting, the mechanical parts can produce uniform and fine concave convex surfaces on the surface of the parts, so that the lubricating oil can be stored, thus improving the lubricating conditions, reducing noise and improving the service life of the machinery.

(5) For some special purpose workpieces, Sandblasting Different reflections or matt can be achieved at will. For example, polishing of stainless steel workpiece and plastic, polishing of jade, matting of wooden furniture surface, pattern pattern on frosted glass surface, and texturing of cloth surface.