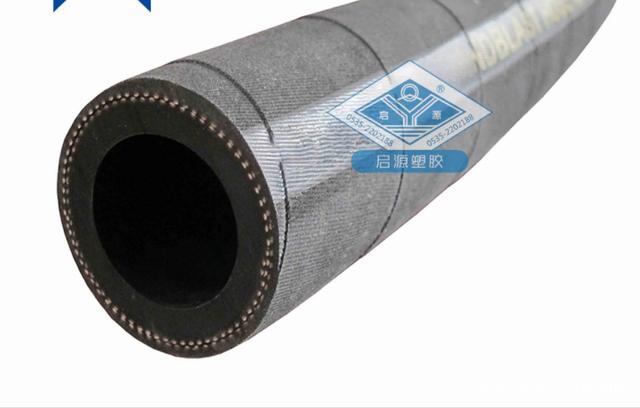

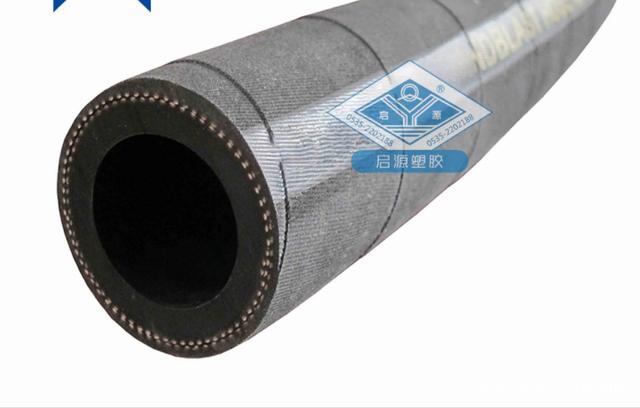

Sandblasting pipe Also called rubber hose for sand blasting, it is suitable for air pressure sand blasting for rust removal, hemp removal, and sand blasting rubber hose for wet sand blasting and dry sand blasting in engineering construction.

Features of sand blasting pipe: the inner rubber is made of cis-1,4-polybutadiene and butyl rubber as the main raw materials, and special reinforcing agent is added. It has the characteristics of high wear resistance, high toughness, etc. It uses high-quality and high-strength cord as the reinforcing layer, which has the characteristics of high pressure resistance, torsion resistance, etc. It uses wear-resistant natural rubber as the outer rubber layer, which has the characteristics of drag resistance, etc.

Use of sand blasting pipe: it is commonly used for workpiece surface cleaning, such as removing residual sand and high carbon layer on the surface of castings, as well as welding seams of weldments, and removing rust and oxide skin.

Classification of sand blasting: it is mainly divided into dry spraying and wet spraying. Wet spraying uses abrasive and water to mix into mortar to prevent metal rust. Corrosion inhibitor shall be added to water. High dry spraying efficiency, rough machining surface, large dust, and more abrasive damage; Wet spraying has little environmental pollution, and has a certain polishing and protection effect on the surface. It is often used for more precise processing.

Temperature range: - 40 ° C~+90 ° C

Product application: sand blasting machine of various specifications and models, industry, mining, civil engineering, agriculture, tunnel and mine operation, etc

1. Do not bend when using, try to keep it straight

2. Pay attention to the use time, the number of sandblasting squares and particle size

Common inner diameter of sand blasting pipe: 19, 25, 32, 39, 48mm