Sandblasting pipe It is an indispensable part of the normal operation of the shotcrete machine. For the so-called shotcreting, the common medium is steel sand and steel shot. What is the abrasion degree of sand blasting and shot blasting on sand blasting pipe (wear-resistant pipe)?

The editor of Laizhou Qiyuan Plastic Products Co., Ltd. will explain to you:

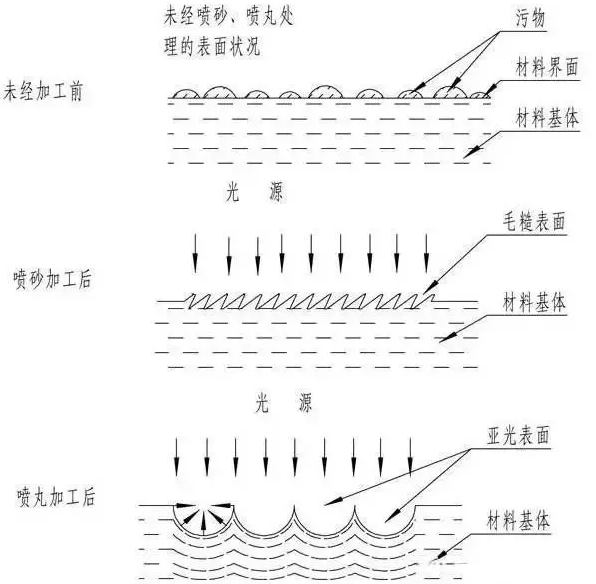

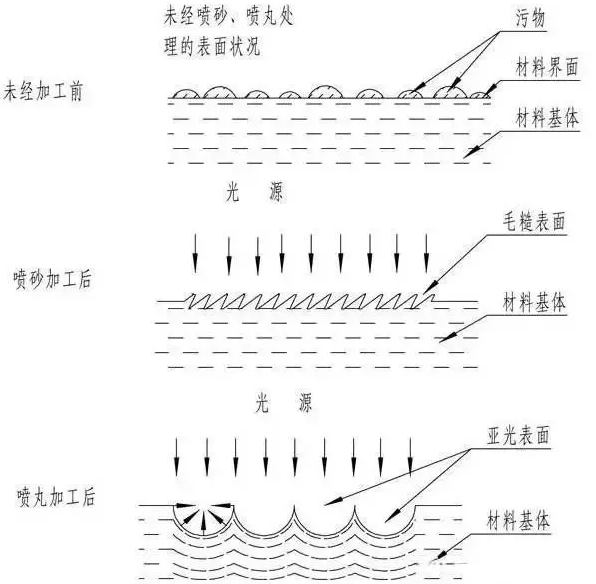

Both shot blasting and sand blasting use high-pressure air or compressed air as power to blow it out at a high speed and impact the workpiece surface to achieve cleaning effect. However, the effect is different due to different media selected. After sand blasting, the dirt on the surface of the workpiece is removed, the surface of the workpiece is slightly damaged, and the surface area increases significantly, thus increasing the bonding strength between the workpiece and the coating/plating.

The surface of the sand blasted workpiece is metallic, but because the surface is rough, the light is refracted away, so there is no metallic luster and the surface is darkened.

The surface of the workpiece after shot peening treatment is also metallic, but because the surface is spherical, part of the light is refracted Abrasion resistant sand blasting hose The most important thing is wear resistance.

Through the comparison of the above figure, it can be seen that:

The rough surface of the sandblasted workpiece is caused by steel sand or quartz sand. The surface of the sprayed material has edges and corners, which can impact the surface of the product. Similarly, it is because the material has edges and corners, which can cause great wear on the wear-resistant layer of the sandblasting pipe.

However, the surface of the workpiece after shot peening is arc-shaped, and the surface of the steel shot is relatively smooth, so it can cause arc-shaped impact on the surface of the product. Compared with steel sand or quartz sand, the wear of steel shot on the wear-resistant layer of the sandblasting pipe is far less than that of steel sand and quartz sand.

Compared with the sand blasting hose of the export wear-resistant standard, under normal use, steel sand can be sprayed for 500 hours; In case of steel shot blasting, shot blasting can be used for 25% more time than sand blasting under the same conditions

It's better on the market now Sandblasting pipe There are some good brands, such as Sanlux, Qiyuan Yatai, and so on. Their wear resistance and quality are very guaranteed.